When selecting a water chiller for cooling a 1500W fiber laser cutting machine, there are several key factors to consider:

1. Cooling Capacity: The chiller must have sufficient cooling capacity to handle the heat load generated by the laser. For a 1500W fiber laser cutter, it needs to have a cooling capacity of around 3-5 kW of the cooling equipment.

2. Temperature Stability: Precision in temperature control is crucial for maintaining the performance and lifespan of the laser. Look for water chillers that offer precise temperature stability of at least ± 1 ℃.

3. Refrigerant Type: Ensure the water chiller uses an environmentally friendly refrigerant. Common options include R-410A and R-134a.

4. Pump Performance: The pump should be able to provide adequate flow and pressure to the laser system. Check the pump's flow rate (L/min) and pressure (bar).

5. Noise Level: Consider the noise level of the water chiller, especially if it will be located in a work environment where noise could be a concern.

6. Reliability and Maintenance: Choose a reputable water chiller brand known for reliability and ease of maintenance. Availability of spare parts and technical support is also important.

7. Energy Efficiency: Energy-efficient water chillers can save on operational costs in the long run.

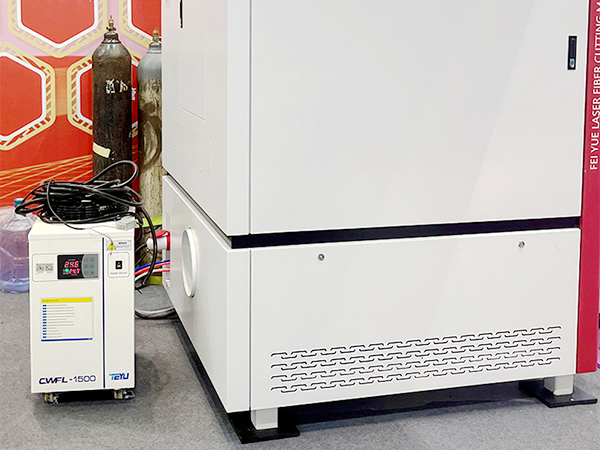

8. Footprint and Installation: Consider the physical size of the water chiller and its installation requirements to ensure it fits well within your space constraints.